Nexus Intelligence

BMW Recalls 36,922 X3s Over Steering Software Glitch

According to a new article from BMWBlog, "BMW is launching a voluntary safety recall covering certain 2025–2026 BMW X3 models after identifying a software weakness in the steering system that, in rare cases, can lead to unintended steering wheel movement while the vehicle is stationary."

2025 BMW X3 M50 xDrive (click to enlarge)

I was able to find a video of the steering wheel issue here:

The recall documentation points to a software-related correction, meaning impacted vehicles should ultimately receive an updated steering system software calibration. If you own a 2025 or 2026 X3, especially an X3 30 xDrive or X3 M50 xDrive, keep an eye out for the official notice. No crashes or injuries have been linked to this glitch so far.

As mentioned by Cars.com, "As a fix, the steering system software will be updated via an over-the-air update or by a dealer for free. BMW will notify owners Feb. 2, 2026, but those with further questions can contact the automaker at 800-525-7417, NHTSA’s vehicle-safety hotline at 888-327-4236, or visit its website to check your vehicle identification number and learn more."

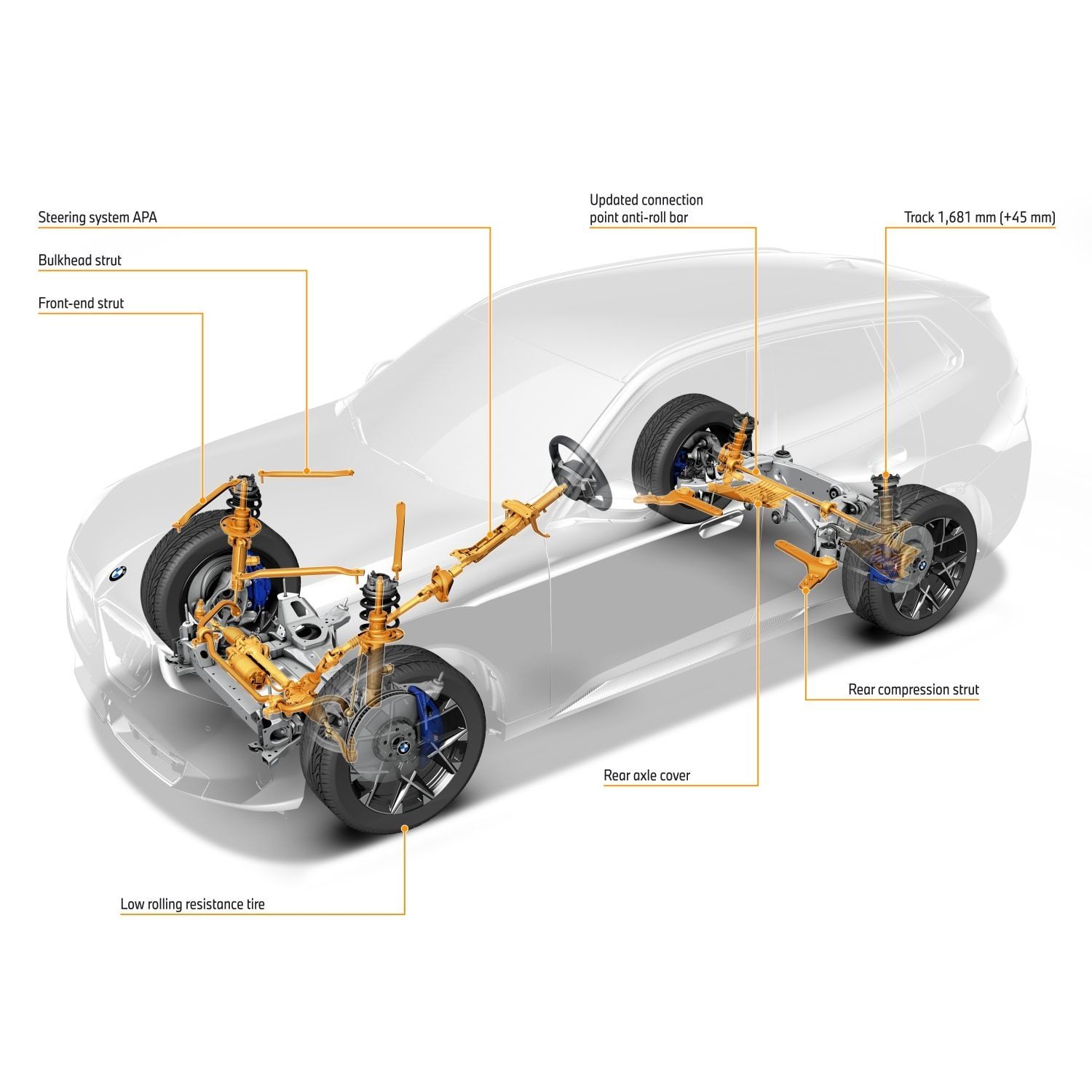

2025 BMW X3 steering software recall illustration

Photo courtesy of autoevolution.com (click to enlarge)

Could Hackers Exploit this Issue?

Modern vehicles like the X3 use electronic control units (ECUs) and networks (e.g., CAN bus) for functions including steering assist. In theory, if a hacker gained physical access (e.g., via OBD-II port) or compromised a weakly secured wireless interface, they could potentially manipulate software behaviors, including triggering or mimicking diagnostic errors. However, BMW's systems include multiple layers of security, like encrypted communications and isolated modules, to prevent such interference. Past automotive hacks (e.g., on other brands) have required sophisticated setups, often involving direct connections rather than over-the-air attacks.

How can BMW avoid this issue in the future?

1. Enhanced Code Testing Protocols:

Adopt comprehensive testing frameworks, including unit testing (for individual code modules), integration testing (to ensure software interacts correctly with hardware like sensors), and system-level testing (simulating real-world scenarios). Tools like automated regression testing could catch issues introduced by updates.

Incorporate fault injection testing, where deliberate malfunctions (e.g., simulated sensor failures) are introduced to verify the software's detection and response mechanisms. This directly addresses the recall's root cause.

Use hardware-in-the-loop (HIL) simulations to test steering software in a controlled environment that mimics vehicle conditions, reducing reliance on post-production discoveries.

2. Improved Change Management Processes:

Implement a rigorous version control and change management system (e.g., using Git with strict branching strategies and peer reviews) to track all software modifications. This ensures that changes to detection algorithms are thoroughly vetted before deployment.

Establish a formal change control board involving cross-functional teams (software engineers, hardware specialists, and safety experts) to evaluate the impact of any updates on critical systems like steering.

Align with standards like ISO 26262 (Automotive Functional Safety), which mandates traceable change management to mitigate risks in safety-critical software.

3. Broader Preventive Measures:

Redundancy and Fail-Safes: Design systems with redundant sensors or backup detection logic to prevent single points of failure. For instance, cross-verifying torque sensor data with other inputs (e.g., wheel speed or accelerometer) could provide an additional layer of safety.

Pre-Production Validation: Expand field testing and beta programs to include diverse driving conditions and edge cases, such as stationary scenarios where the issue manifested. Collaborate with third-party auditors for unbiased validation.

Post-Deployment Monitoring: Leverage OTA capabilities not just for fixes but for proactive monitoring—e.g., collecting anonymized telemetry data from vehicles to detect anomalies early via AI-driven analytics.

Supplier and Supply Chain Oversight: If the torque sensor or related components come from external suppliers, enforce stricter quality checks and joint testing protocols to ensure hardware-software compatibility.

Cultural and Training Shifts: Foster a "safety-first" engineering culture through regular training on emerging software risks, especially as vehicles become more software-defined. This could include lessons learned from past recalls integrated into development workflows.

BMW adheres to ISO 26262, the international standard for functional safety in automotive electrical and electronic systems, which directly addresses many of the recommendations above so it's highly likely BMW will incorporate such changes as part of their ongoing safety and quality processes.

Do you need any IT help?

- Contact me here for a FREE consultation: https://cybernexusadvisors.eo.page/contactform

- Sign up for my recommended anti-malware solution, Malware Bytes premium, and get 55% off:

https://share.malwarebytes.com/x/3Wc58k

- If this article was helpful to you please use my Amazon affiliate link. Shop as normal on Amazon and I make a small commission of whatever you purchase:

Thank you for reading,

Dave Bullis, CISSP

Founder & Principal Consultant

Sign up for The Nexus Intelligence

Stay ahead of cyber risks and industry trends by subscribing to Cyber Nexus Advisors’ expert updates and strategic guidance.